FEATURES AND OPTIONS

Add-Ons that Create Efficiency and Cost Savings

At reACTIV Laser Systems, our array of industry-leading hardware and software features set us apart in the market. Whether it's precision cutting, engraving, or marking, our systems consistently deliver top-tier performance at a competitive cost. We pride ourselves on offering a wide range of options that cater to every need and budget, ensuring that our customers can always find the ideal solution for their specific requirements.

Look below for great options.

FEATURES AND OPTIONS

RLS 500+ Laser Exhaust

reACTIV Laser Systems Industrial Exhaust Systems are purpose built and designed specifically for laser processing extraction. High volume flow with large format filters to ensure extraction rate and filter cost is maximized.

Exhaust Unit Features

120 VAC / 230 VAC primary power

45-65 dB noise level

Remote interface to laser system

~300 CFM

3 Stage filter system

Active Carbon filter for air scrubbing

~22" wide x 29" deep x 51" tall

~330 lbs / 150 kg

Mounted to rolling casters

RLS 230+ Laser Exhaust

reACTIV Laser Systems Industrial Exhaust Systems are purpose built and designed specifically for laser processing extraction. High volume flow with large format filters to ensure extraction rate and filter cost is maximized.

Exhaust Unit Features

120 VAC / 230 VAC primary power

~60 dB noise level

Remote interface to laser system

~150 CFM

2 or 3 Stage filter system

Optional Active Carbon filter for air scrubbing

~14" wide x 26" deep x 44" tall

~190 lbs / 90 kg

Mounted to rolling casters

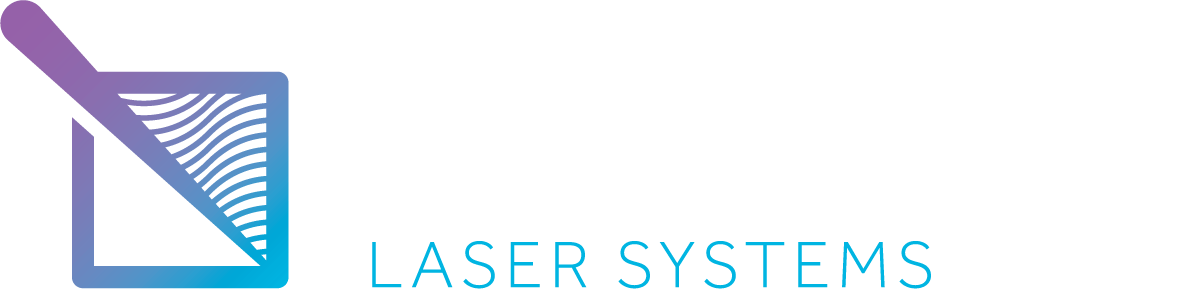

Precision Dual Axis Rotary Trunnion

reACTIV Laser Systems precision dual axis rotary trunnion is a purpose built rigid part positioning system. Engineered with a heavy duty bearings and gearing, reACTIV Laser Systems ensures stability and repeatability of the machine for today's industrial manufacturing needs. With countless industry leading hardware and software features reACTIV Laser Systems lead the market in cost versus capability in every scenario.

Rotary Axis Features

Servo controller and motor system

Repeatability of <+/- 6 second of arc

Tilt range of 190° (±95° from vertical)

Swivel - infinite range

Sealed against dust and coolant spray to IP65

101:1 gear ratio

Precision Rotary Axis - S

reACTIV Laser Systems precision rotary axis is a purpose built rigid part positioning system. Engineered with a heavy duty bearings and gearing, reACTIV Laser Systems ensures stability and repeatability of the machine for today's industrial manufacturing needs. With countless industry leading hardware and software features reACTIV Laser Systems lead the market in cost versus capability in every scenario.

Rotary Axis Features

Servo controller and motor system

Repeatability of <+/- 6 second of arc

Tilt range of 190° (±95° from vertical)

Swivel - infinite range

Sealed against dust and coolant spray to IP65

101:1 gear ratio

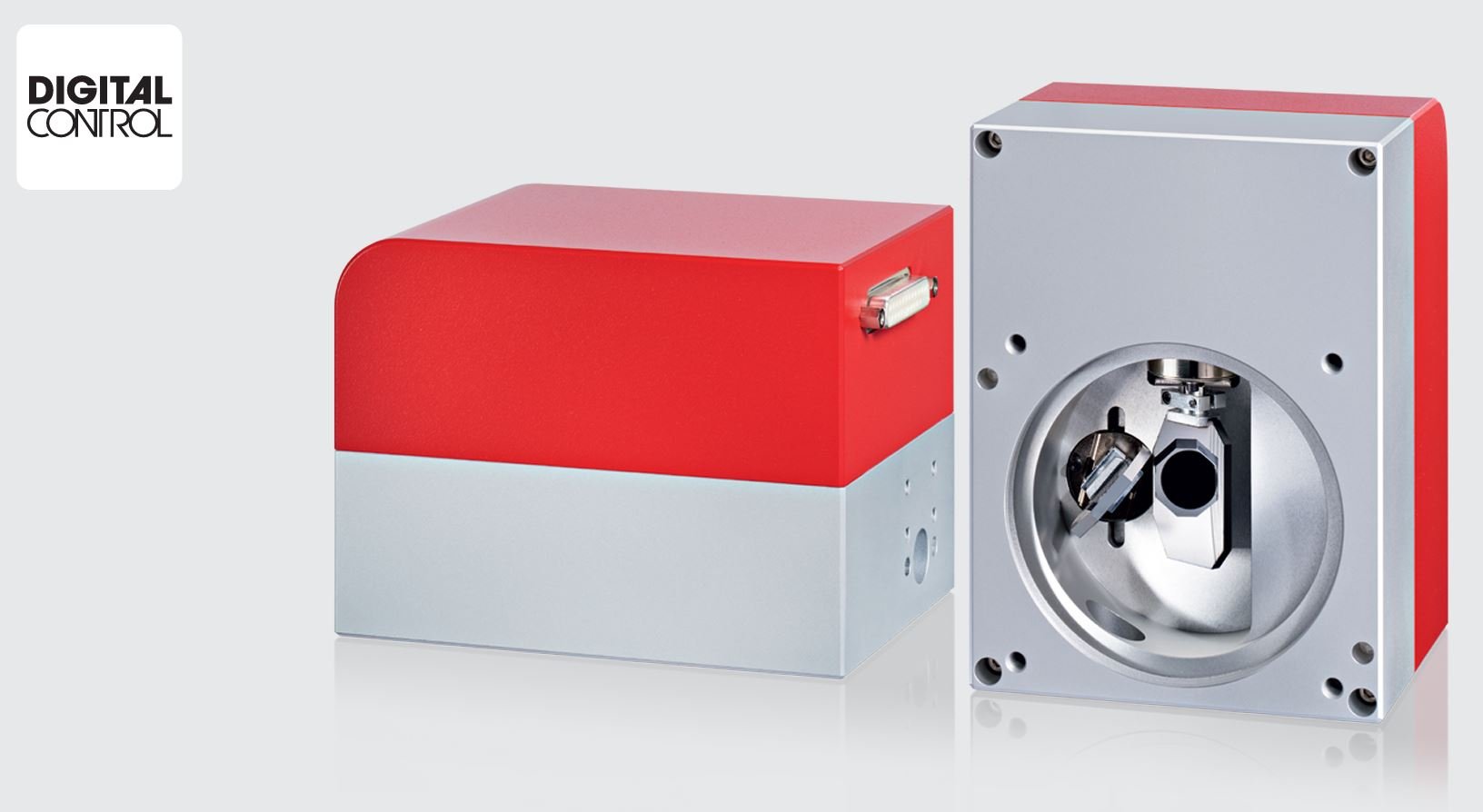

laserVIEW Integrated Camera System

reACTIV Laser Systems laserVIEW product is an integrated vision system for laser marking and engraving. Engineered as a through the lens system, the camera view is overlaid onto the laser markign SW canvac giving the operator a realtime view of the part currently in process. With countless industry leading hardware and software features reACTIV Laser Systems lead the market in cost versus capability in every scenario.

Software Features

Camera images stitched together

Image covers complete laser marking / engraving field

Laser processing object overlay directly to image

Accuracy defined via camera resolution and lens selection

Pick to fit functions for usability

reACTIV Laser Operations Software

reACTIV Laser Systemsoperations software is a purpose built software tool for all lase rprocessign needs. Engineered with beyond industry stadnard features and capabilities, reACTIV Laser Systems ensures quality and capabilities for today's industrial manufacturing needs. With countless industry leading hardware and software features reACTIV Laser Systems lead the market in cost versus capability in every scenario.

Software Features and Capabilities

Laser MarkingLaser Engraving

3D Laser Engaving

Matrix / array features

Tiling features

Single line & True Type Font features

Vector Graphic Import - DXF, DWG, SVG, CGM

Image Import - JPG, BMP, GIF, PNG

2D Barcodes - ECC Compliant data matrix, QR Codes

1D barcodes

Variable data processing (static & dynamic)

Automatic Data / Time processing

Integrated User Logins & password control

Definable user groups & roles

3D Digital Scan Head

The 3D Digital Scan Head offers superior performance, consistency and lifespan. With the latest technology version galvanometers performance and stability is unmatched.

Beam Delivery

3 Axis, Digital Scan head, definabel input aperture

10m/sec processing speeds

Scan tracking, error compensation

Field sizes from 2" x 2" to 36" x 36"

definable laser spot size

Control System

Solid State Stand ALong Controller

Windows 10 Pro / Windows 11 Operating system

Temp 90 F, to 85% humidity (non condensing)

SL2-100 control protocol

Solid State Laser Controller

The Solid State Laser Controller offers countless features with realtime scan and laser control. With laser control up to 16 MHz the solid state controller has the capability and responsiveness for any application.

Scan Control Features

Parallel or high speed serial control

Control up to 5 Scan Head simutaniously

Monitors and compensates for tracking error for all axis individually

Variable delay capability / Sky writing

Laser Power calibration

Control and Interface Features

cPCI interface or standalone operation

Ethernet connectivity

2x16 bit I/O ports in 3.3 or 5 VDC TTL configuration

1x16 bit I/O port in 24 VDC or 5 VDC configuration

2x quadrature decoders for marking on the fly

RS232 v.24, USB 2.0

Operation with Windows 10 / 11 32 or 64 bit systems

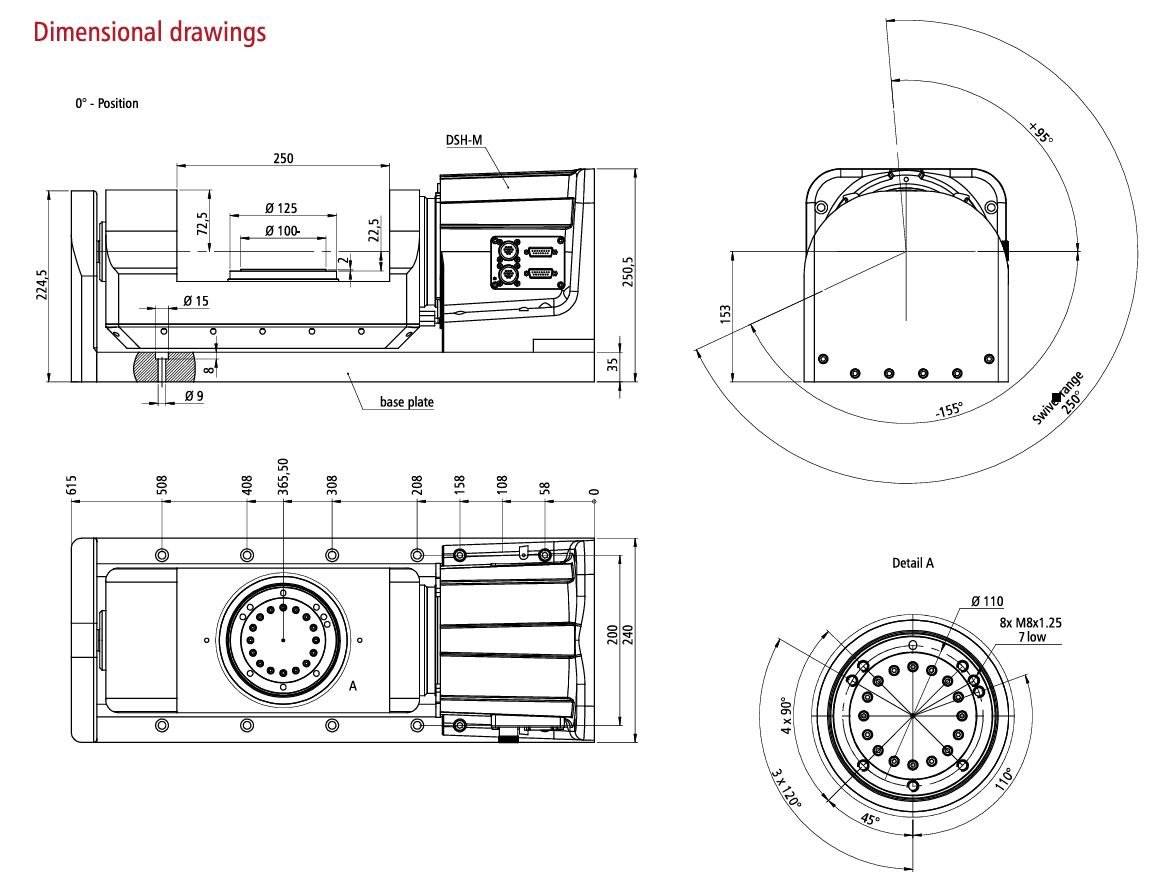

Precision Digital Scan Head

The Precision Digital Scan Head offers superior performance, consistency and lifespan. With the latest technology version galvanometers performance and stability is unmatched.

Beam Delivery

2 Axis, Digital Scan head, definabel input aperture

10m/sec processing speeds

Scan tracking, error compensation

Field sizes from 2" x 2" to 18" x 18"

Definable laser spot size

Control System

Solid State Stand ALong Controller

Windows 10 Pro / Windows 11 Operating system

Temp 90 F, to 85% humidity (non condensing)

SL2-100 control protocol

Low noise and axis drift

Standard Scan Head

The Standard Scan Head offers superior performance, consistency and lifespan. With the latest technology version galvanometers performance and stability is unmatched.

Beam Delivery

2 Axis, Digit Scan head, definable input aperture

10m/sec processing speeds

Scan tracking, error compensation

Field sizes from 2" x 2" to 18" x 18"

Definable laser spot size

Control System

Solid State Stand ALong Controller

Windows 10 Pro / Windows 11 Operating system

Temp 90 F, to 85% humidity (non condensing)

XY2-100

Low noise and axis drift

Continue Exploring

Ready To Get Started?

Let's get in touch to get a jump start on your project.