LASER WORKSTATIONS

Leading the Market in Cost versus Capability - in Every Scenario

Engineered with a heavy tube steel frame, reACTIV Laser Systems ensures stability and repeatability of our laser workstations for today's industrial manufacturing needs.

With countless industry leading hardware and software features reACTIV Laser Systems lead the market in cost versus capability in every scenario.

Look below for great options.

LASER WORKSTATION OPTIONS

Industrial Workstations

The WS50 Industrial Workstation is a purpose built rigid workstation. Engineered with a heavy tube steel frame, reACTIV Laser Systems ensures stability and repeatability of the machine for today's industrial manufacturing needs. With countless industry leading hardware and software features reACTIV Laser Systems lead the market in cost versus capability in every scenario.

Workstation Features

2” tube steel frame

3/4” main platten

14 ga steel paneling

Powder coated finish

Automatic or Manual door

Fully enclosed axis system

Ergonomic Sit / Stand / Tilt monitor, keyboard and mouse interface

2" x 2" to 36" x 36" (X / Y 2D Heads)

2" x 2" to 36" x 36" x (+/-) 1.5" (X / Y / Z 3D Heads)

120, 208, 240 or 480 VAC configurations

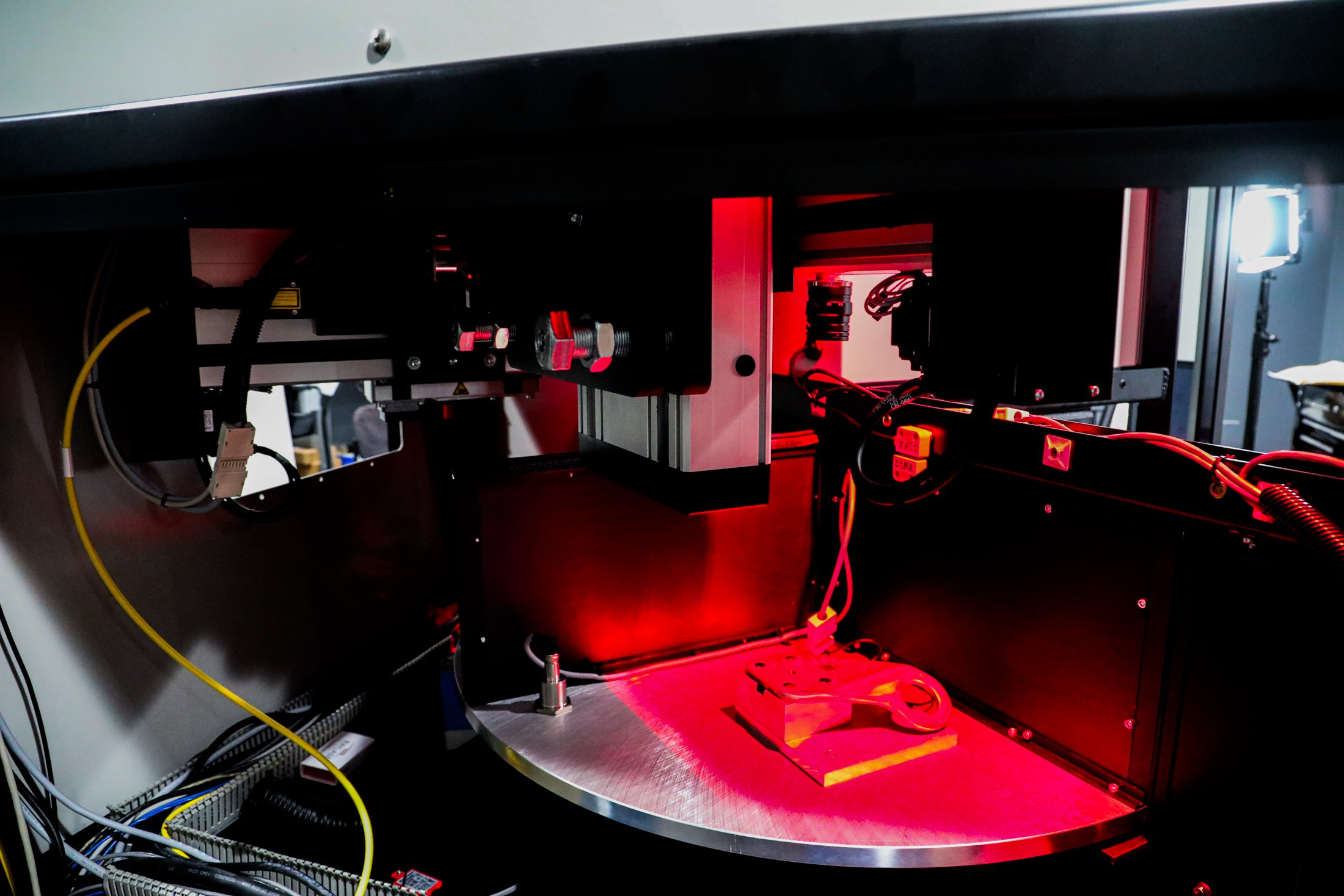

Automatic Rotary Dial Workstations

The WS50 Industrial Workstation is a purpose built rigid workstation. Engineered with a heavy tube steel frame, reACTIV Laser Systems ensures stability and repeatability of the machine for today's industrial manufacturing needs. With countless industry leading hardware and software features reACTIV Laser Systems lead the market in cost versus capability in every scenario.

Workstation Features

2" tube steel frame, 3/4" main platten

14 ga steel paneling

Powder coated Finish

18" & 36" Standard Dial

Customizable dial sizes & wieght based on applciation

Ergonomic Sit / Stand / Tilt monitor, keyboard and mouse interface

Safety Light Grid system

Large formatTouch Screen HMI

Rotating baffel wall for safety

2" x 2" to 36" x 36" (X / Y 2D Heads)

2" x 2" to 36" x 36" x (+/-) 1.5" (X / Y / Z 3D Heads)

120, 208, 240 or 480 VAC configurations

OEM Laser Systems for Integration

reACTIV Laser Systems are market leading systems. Offering the highest beam quality and power stability available in the industry. With countless industry leading hardware and software features the reACTIV Laser System leads the market in cost versus capability in every scenario.

System Features

IR, Green, UV and Ultra Short Pulse laser source options

Laser wattages 20-600 watts air / water cooled

Free standing, rolling 19" rack confguration or NEMA 12 enclosure

Powder coated finish

Solid State Stand Alone control system

Windows 10 / 11 Pro PC system for programming

Integrated Class III safety control system

Multiple 8x8 I/O ports for Autmation

Job level or system level I/O control

2" x 2" to 36" x 36" (X / Y 2D Heads)

2" x 2" to 36" x 36" x (+/-) 1.5" (X / Y / Z 3D Heads)

120, 208, 240 or 480 VAC configurations

Custom Industrial Workstations

reACTIV Laser Systems Industrial Workstation is a purpose built rigid workstation. Engineered with a heavy tube steel frame, reACTIV Laser Systems ensures stability and repeatability of the machine for today's industrial manufacturing needs. With countless industry leading hardware and software features reACTIV Laser Systems lead the market in cost versus capability in every scenario.

Workstation Features

2" tube steel frame, 3/4" main platten

14 ga steel paneling

Powder coated Finish

Automatic or Manual door

Fully enclosed axis system

Ergonomic Sit / Stand / Tilt monitor, keyboard and mouse interface

2" x 2" to 36" x 36" (X / Y 2D Heads)

2" x 2" to 36" x 36" x (+/-) 1.5" (X / Y / Z 3D Heads)

120, 208, 240 or 480 VAC configurations

Basic Table Top Enclosure

The Basic Table Top Enclosure is a market driven product. Engineered with quality and space saving features, reACTIV Laser Systems ensures stability and repeatability of the machine for today's industrial manufacturing needs.

With countless industry leading hardware and software features reACTIV Laser Systems lead the market in cost versus capability in every scenario.

Workstation Features

Formed Sheet metal, powder coated

Powder coated Finish

Powered electric door

Integrated Laser Safety

Working area of ~16" x 8"

~Max part height of 7"

Footprint ~17” wide x 24” deep x 24” tall

Continue Exploring

Ready To Get Started?

Let's get in touch to get a jump start on your project.